Hey, we're WASP - Melbourne's Dedicated Mobile Blasting Company

At WASP (Wet Abrasive Surface Preparation), we've been Melbourne's industry-leading mobile sandblasting specialists since the late 1980s. We were the first dedicated commercial and industrial blasting company in Melbourne, pioneering onsite sandblasting solutions that come to you.

While we use the term "sandblasting" as it's commonly understood, we actually use safe, non-silica abrasive materials - never sand - ensuring the health and safety of our team and clients.

Mobile Sandblasting

From bridges, ships and building facades to tunnels and industrial facilities, we can abrasive blast anywhere using our comprehensive range of mobile wet sandblasting applications and cutting-edge dustless technologies.

Our specialised dustless blasting equipment includes custom-built enclosures and containments that conform to the most stringent health and safety regulations - we can work over and around almost anything, from grandstands to industrial facilities and commercial buildings.

✓ Dustless Technology: Up to 95% dust reduction

✓ Eco-Friendly: Zero environmental harm

✓ ISO Certified: Industry benchmark standards

✓ Fully Mobile: We come to your location

✓ Expert Team: 35+ years experience

Your Comprehensive Mobile Blasting Services

Mobile Sandblasting

Complete onsite blasting solutions using state-of-the-art wet abrasive systems. We bring everything to your location with full containment capabilities.

We proudly boast a trail of satisfied clients from large multi-national building contractors to home and small business owners.

Our domestic and residential blasting services give home-owners and small business owners the effects they are looking for.

Professional surface preparation and restoration services for cars, vehicle parts, and commercial fleets, with precision care.

Restoration & Cleaning

Comprehensive cleaning and restoration services for various surfaces and structures across Melbourne.

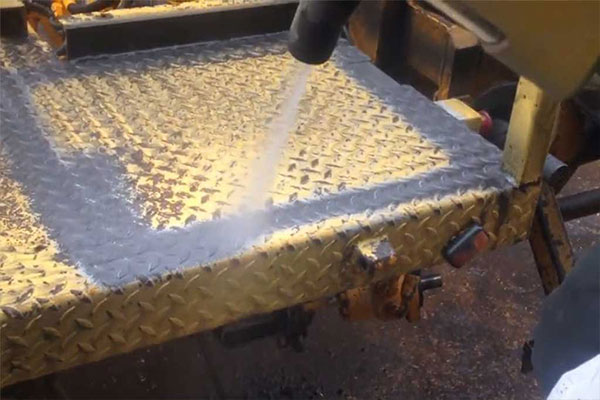

Our heavy machinery blasting services can be applied to big and small projects. Valuable equipment treated with care.

Expert paint stripping services using specialty equipment for all types of residential, commercial and industrial surfaces.

Safe, effective graffiti removal that eliminates vandalism without damaging underlying surfaces or surrounding areas.

We offer professional line mark removal from any surface such as roads, pavements, parking lots and more.

Professional concrete sandblasting services to clean, restore, and prepare surfaces for finishing. Expert techniques ensure precision and quality results.

We offer limitless design possibilities with intricate patterns or elegant designs using blasting techniques, enabling your imagination to bring your concrete surfaces to life.

Reveal the hidden beauty and durability of aggregate concrete surfaces, ideal for enhancing residential and commercial properties with unique aesthetic appeal.

WHAT OUR CLIENTS SAY

Restoration & Cleaning Services

Cleaning and maintaining a surface’s structure can be hard work, especially if you don’t know exactly what to do and where to get started.

Some structures require special care, which is why bridge refurbishment projects can truly benefit from our expertise.

Protecting a hull from marine growth and seawater is best done by employing boat antifouling experts.

Keeping brick in good condition is not always easy. Brick restoration services will reinstate it to its former glory.

Bitumen removal from roads, driveways and commercial surfaces using safe, chemical-free wet blasting technology.

A swimming pool no longer looks its best? A comprehensive pool restoration can make it appear as good as new.

High pressure water blasting is a super effective way to remove dirt, paint, scale and various other unwanted materials from surfaces.

Whenever domestic methods are not enough, professional driveway cleaning is the way to go for a long-lasting effect.

We offer waterproofing preparation of surfaces with abrasive blasting - an efficient and safe way to get the job done.

What Makes Our Sandblasting Services Stand Out from the Rest:

Our effective and meticulous workmanship

We use The latest abrasive blasting equipment and technologies

We're Highly experienced and trained specialists

We guarantee zero damage to your surface

Our blue-ribbon customer satisfaction policies

We offer Reasonable and competitive prices

Our friendly and approachable representatives

Our Services tailored to your requirements

We're OHS compliant

We ensure no potential hazards

Mobile Sandblasting Services - FAQs

Businesses We've Worked with